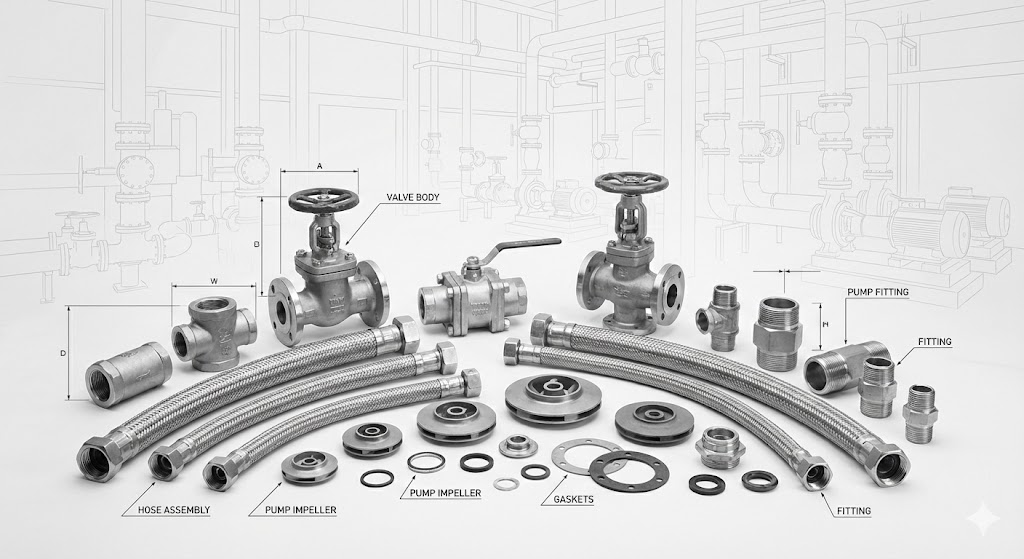

Manufacturer of components for the energy sector

With a strong presence in the energy sector, we operate as a subcontractor for the manufacturing of equipment related to the oil, fluid, and gas industries. Our components are primarily used in valve systems, flexible piping, and pumps.

Our production capacity

We handle batch sizes ranging from 1,000 to 1 million parts per year.

Machining range: Ø10 to 160 mm.

Examples of components machined in our facility: fittings, valves, nuts and other components, connector bodies, pipe fittings, connectors, gas meter parts, temperature sensors and probes, as well as oil burner pump components.

To know more

Our machines

range

We utilize both CNC and conventional multispindle lathes for batch sizes exceeding 50,000 units. Our equipment includes, for example, 8-spindle Tornos MultiSwiss and 6 or 8-spindle Gildemeister lathes. For series of 50,000 parts or fewer, we prioritize our twin-spindle CNC machines, such as Biglia and Deco 2000 lathes.

Our

machined materials

In the energy sector, steel, aluminum, stainless steel, and brass are the most commonly used materials.

Steel :

11SMn37/ 1.0736 /S300

11SMnPb37/ 1.0737/S300Pb

11SMnPb30/ 1.0718/ S250Pb

11SMn30/ 1.0715/ S250

44SMn28/ 1.0762/ 45MF6.3

36SMn14/ 1.0764/ 35MF6

Aluminum:

EN AW-6060

EN AW-2030

EN AW-2011

EN AW-7075

Stainless steel :

1.4307

1.4541

1.4404

1.4305

1.4021

Brass :

CW710R

CW713R

CW724R

CW624N

CW606N

CW612N

CW614N

Additionnal

services

A wide range of surface treatments provided according to your needs through our local partners:

Hard chrome plating

Electroless nickel plating

Nickel plating

Black oxide coating (Burnishing)

Zinc plating