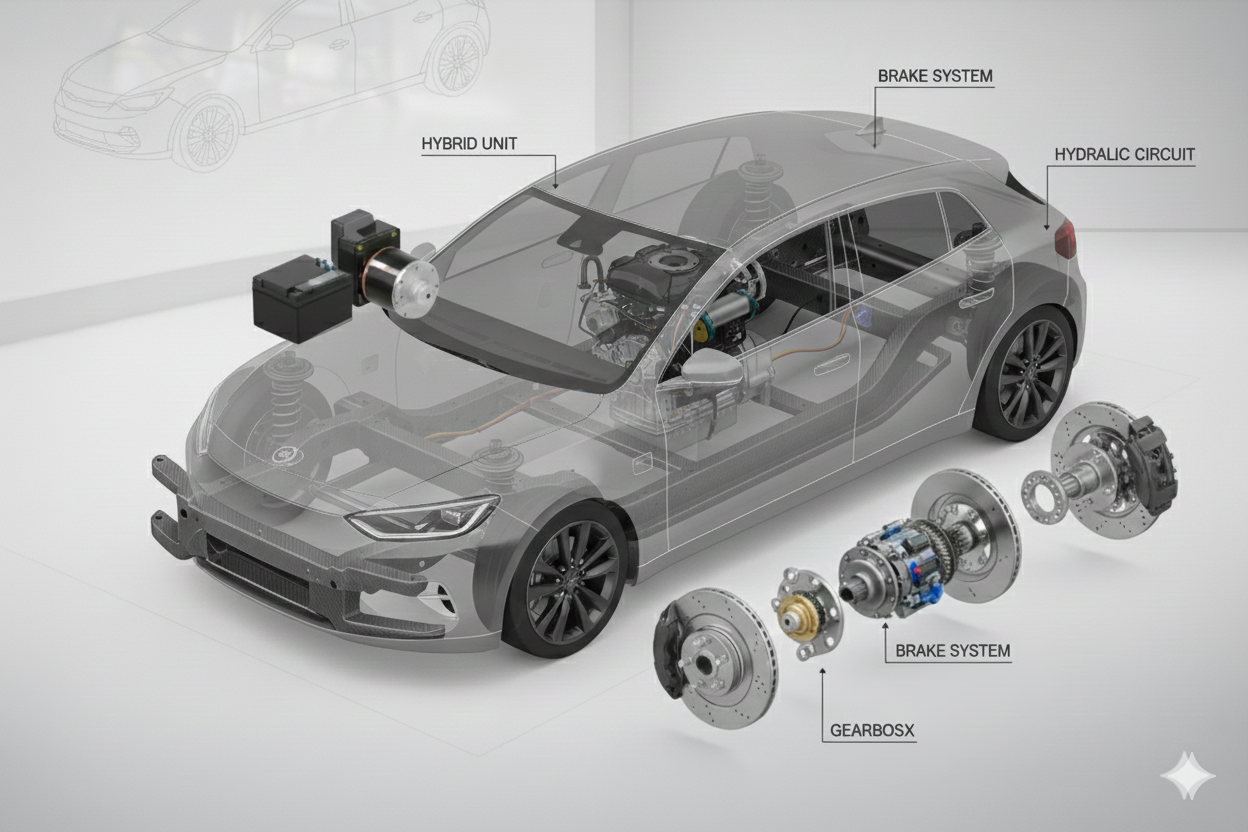

Automobile component manufacturer

Our expertise and technical know-how enable us to manufacture precision turned parts for the demanding automotive and heavy-duty vehicle sectors. Our competitiveness allows us to continuously expand our international market share.

We are IATF 16949 certified.

Our production capacity

We manufacture components for a wide range of applications, including electric and hybrid powertrains, braking systems, hydraulic circuits, and gearboxes.

Our machining range covers diameters from Ø10 mm to Ø160 mm.

Examples of components machined in our workshops:

Spacers / Standoffs, Connectors / Sealed connectors, Plugs / Caps, Nuts, Bushings / Rings, Check valves, Valves, Washers, Tubes / Sleeves, Inserts, Pistons, Nozzles / Jets

To know more

Our machine

range

Our workshop is equipped with three different types of machines, allowing us to offer comprehensive precision turning solutions:

Our twin-spindle CNC machines can handle production runs starting from 1,000 parts.

Our traditional and CNC multi-spindle lathes enable us to support high-volume production of 100,000 parts and more.

Quality

at Monnet

Certified to IATF 16949 (automotive) and ISO 14001 (environmental), we meet the most demanding requirements for quality, cost, and delivery (QCD).

Our quality-driven culture ensures a ‘zero-defect’ commitment. Through optimized internal processes and advanced inspection equipment, we provide 100% traceability and parts securing.

Our quality laboratory is equipped with 3D coordinate measuring machines (CMM), Keyence vision systems, contour tracers, roundness testers, and ATEC machines.

Our machined materials

For the automotive sector, we primarily machine aluminum, steel, stainless steel, and brass

Additional

services

We offer component assembly (such as seals and gaskets) directly within our workshop.

In collaboration with our local partners, we also offer secondary operations, including heat and surface treatments.